About

Saving is Earning

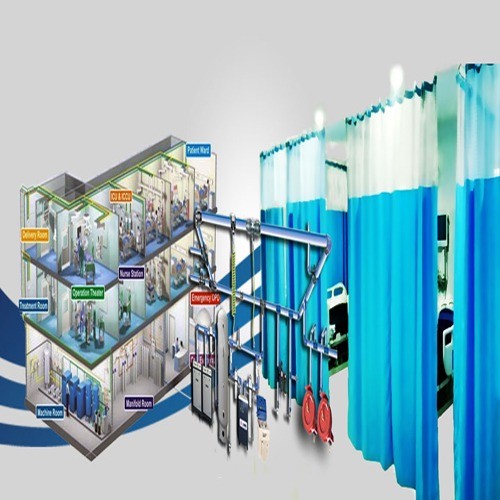

Every hospital is concerned about up time of its medical gas supply and rightly so. This also leads hospitals to be less concerned about huge amount of leakages. The leakage of gases always goes unnoticed by the hospital which is a silent expense leading to a huge loss to the institute. To address this issue, NABH under FMS 6f has made it mandatory to perform Medical Gas Audit once an year at every hospital.

For example a 2 litres per minute leakage in such places leads to leakage of Oxygen equivalent to Two “B” Type cylinder per day. Leakage in 10 such places leads to wastage of O2 up to 5 Bulk Cylinders per day… Which leads to a monthly wastage of Rs. 75000/- with price of each Bulk Cylinder refilling at Rs. 500/- cylinder.

As part of audit, we identify and arrest the leakage of gases that would precisely identify and quantify the leakage in litre per minute across your hospital.

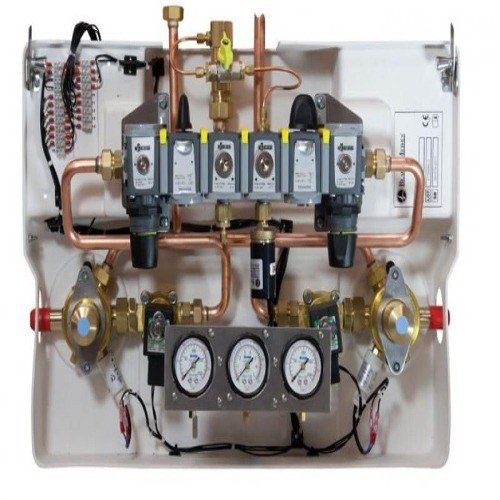

We use proprietary, specialized leak testing device, which has proven its efficacy in identifying leaks across variety of gas pipelines.

- Testing Gas pipeline

- Testing of all Gas Outlet Points

- Testing of Pipelines at all Isolation Valves

- Testing of Alarm panels

- Testing for leakage at Flow meters

- Testing for leakages at Ventilators

- Testing for leakages at Vacuum units

- Testing of leakage at Oxygen

- Testing of leakage at Air

- Testing of leakage at Air Drier

- Testing of leakage at Vacuum receiver